Products

We provide turn-key, integrated systems that include all hardware, software, excitation, and camera required to perform effective NDT. In our 25+ years of experience providing systems to customers around the world, we’ve learned that thermography is not a ‘one size fits all’ endeavor. We work closely with our customers to match systems and components with their specific requirements and help them integrate thermography into their NDT/quality process.

In addition to conventional NDT applications, customers also use our systems to address some of the most challenging materials characterization problems, often considered beyond the range of thermography. In these cases, when solutions didn’t exist, we invented them, building from fundamental physics and engineering principles to develop innovative hardware and software solutions that have received international acclaim, awards, and independent validation. Our products build on these innovations, e.g. our patented Precision Flash Controller®, Thermographic Signal Reconstruction® method, Large Area Projection Thermography, and Ultra-High-Speed acquisition technology, to provide capabilities and results unsurpassed in the field.

NDT Systems

Real systems for real-world problems

TWI Software

More than a pretty picture

NDT Systems

TWI systems range from simple, handheld inspection units to fully automated test cells and laboratory systems for materials characterization. The key is finding the right tool to meet your application needs. We work closely with our customers to fully understand their specific requirements so that we can provide the right tool for the right job. Contact us to further discuss your specific application.

EchoTherm®

The Standard of Excellence

- Flash, Step, or Modulated Heating

- Thermographic Signal Reconstruction® (TSR®)

- Powered by MOSAIQ®

- Virtuoso® for Advanced Material Analysis and Characterization

- Measure Flaw Area/Depth or Material Properties

- Optimized for SysCheckIRTM

- Automation Enabled

- Compatible With Leading IR Cameras

- LabView, MATLAB and Visual Basic Compatible

- CE compliant

ThermoScope®

Lab Performance in a Compact Package

- Flash Heating

- Fast / Real Time Inspection

- Single Operator / Easy to Use

- Lightweight

- Thermographic Signal Reconstruction® (TSR®)

- Powered by MOSAIQ®

- Virtuoso® for Advanced Material Analysis and Characterization

- Measure Flaw Area/Depth or Material Properties

- Optimized for SysCheckIRTM

- Automation Enabled

- LabView, MATLAB and Visual Basic Compatible

- CE compliant

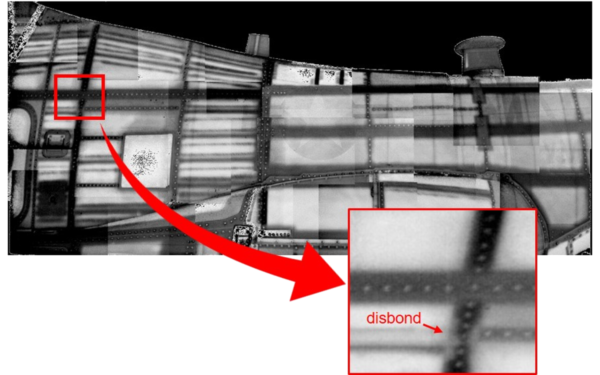

ProjectIRTM/LASLATTM

Large-Standoff, Large-Area Thermography

- NDI Methodology: Pulsed Thermography

- Non-contact, no gantry or creeper required

- Coverage Area: 11.2 ft x 8.4 ft @ 10 ft standoff distance

- Inspection Rate: 7 ft^2/min

- Easily configured for multi-platform inspection

- For fluid ingress, delamination, impact damage

- Winner of the 2016 DoD Maintenance Innovation Challenge

- Powered by MOSAIQ®

- Virtuoso® for Advanced Material Analysis and Characterization

- Optimized for SysCheckIRTM

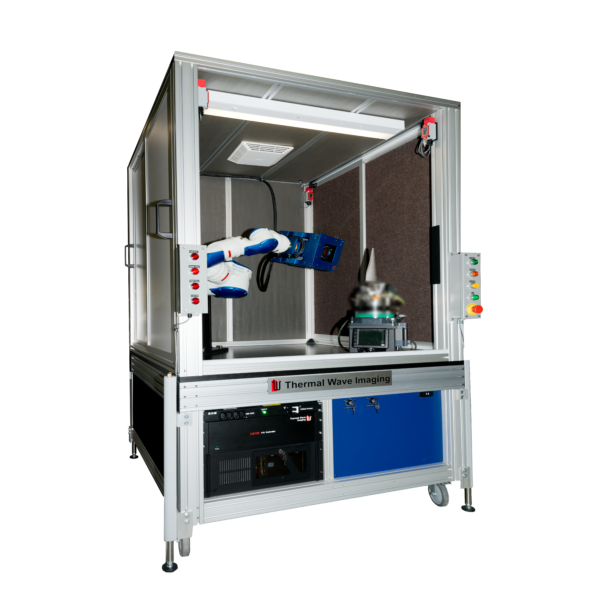

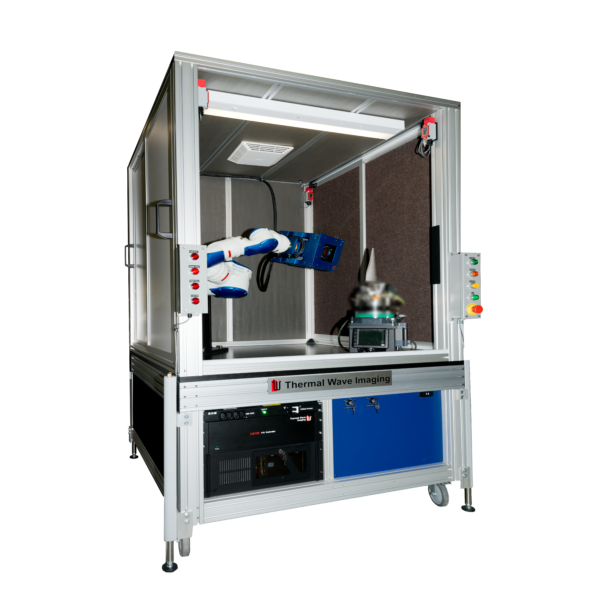

TAFIS®/T3S®

Revolutionizing Turbine Airfoil Inspection

Features

- Fully automated, robotic inspection station – 7 axis

- Automated defect recognition of blocked cooling holes

- Precise, reliable and fast – cycle times as low as 5 sec.

- Modular fixturing for rapid part change-out

- User programmable

- CE compliant

VoyageIR Pro®

NDT on the Go

- TWI Dynamic Step Heating

- TSR® Signal Processing

- MOSAIQ® Compatible for Large Areas

- Simple Touch Screen User Interface

- Lightweight/ Single Case Transport

- Self-contained/ single operator

- Low cost

Thermography System Performance Standards Based on ASTM E2582-19

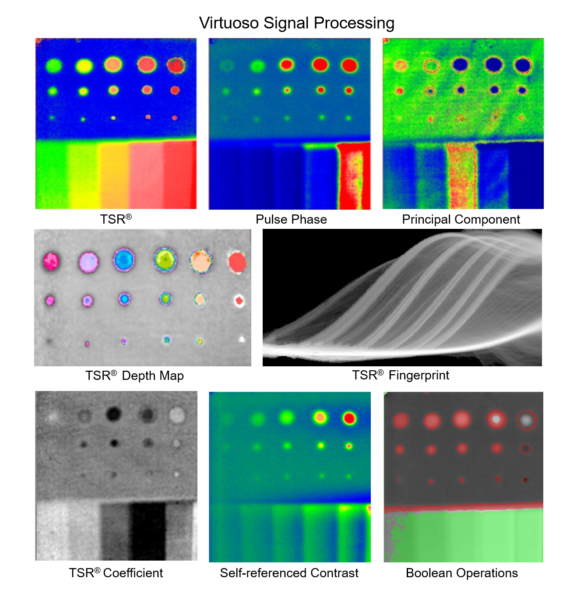

TWI Software – Powered by TSR®

See the Forest and the Trees!

MOSAIQ® simplifies your NDT inspection using built-in analysis, measurement, and visualization tools.

- Thermographic Signal Reconstruction® (TSR®) Processing

- Fast, real time inspection

- For Flash, Step, or Modulated Heating

- Compatible with common factory automation platforms

- Programmable Inspection and Analysis Routines

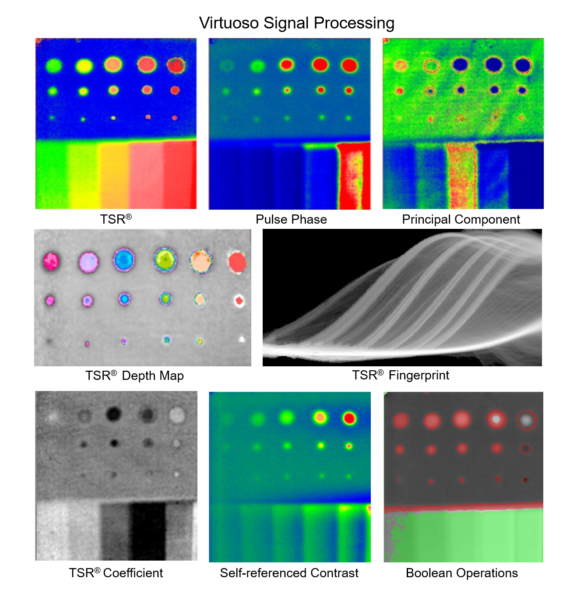

The Ultimate Toolkit for Advanced Thermography

- Thermographic Signal Reconstruction (TSR®)

- Automated Flaw Sizing

- Real-time Analysis

- Analysis of Flash, Step, or Modulated Data

- Multi-scale Contrast Analysis

- Material Characterization

- Pulse Phase and Principal Component Analysis

- Boolean Operations

- Signal / noise Analysis and Optimization

- Compatible with EchoTherm®, ThermoScope®, MOSAIQ®

- Programmable through Matlab, Labview, VBA, C++, Python