Technology

TWI is the leading innovator in the field of Thermographic NDT and the premier solution provider for the most demanding applications in the aerospace, power generation and automotive industries. Building on a physics-based approach to signal processing, dedicated hardware development and application-specific algorithms and procedures, TWI has deployed state-of-the-art inspection solutions for the field, factory floor and large-scale advanced manufacturing around the world for over two decades.

Thermographic Signal Reconstruction® (TSR®)

TWI’s patented Thermographic Signal Reconstruction (TSR) method has been widely recognized as a breakthrough in the field of thermography. TSR performance for flaw detection far surpasses that of conventional approaches, which rely on detection of “hot spots” in the IR image sequence. While conventional thermography is adequate for some simple inspection tasks, it often lacks the accuracy, sensitivity and repeatability required to “meet or exceed” the performance of established inspection methods, such as ultrasound. Introduced by TWI in 2001, the TSR method addresses these limitations, and allows an unprecedented degree of sensitivity, depth range and resolution of subsurface defects. The introduction of TSR has played a significant role in the growth of thermography in real-world manufacturing and in-service inspection applications. In addition to flaw detection, the quantitative nature of TSR enables material characterization, including precise measurement of thickness, defect depth and thermal diffusivity in a wide range of composites, metals, polymers, ceramics and advanced materials.

Large Area Inspection

Advanced Flash Technology

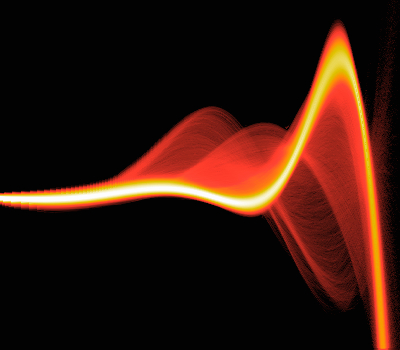

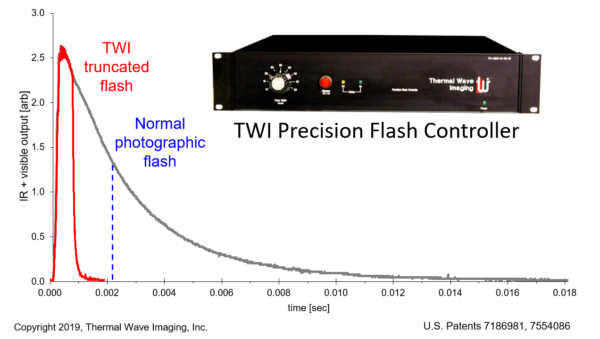

The flashlamps used in most thermography systems are designed for commercial photography, and can result in excessive saturation of the IR detector and nonuniform heating of the target. TWI flash technology was developed specifically for thermography. Our Precision Flash Controller (PFC) provides a flash pulse that can be truncated to a duration of less than 1 msec without loss of spectral components. Our proprietary flashlamp design provides the highest degree of uniformity to the target in the shortest possible pulse.

The combination of the patented TWI PFC and flashlamp technology enables precise measurement of transient or high-speed events that are unmatched using conventional approaches.

Turbine Airfoil Inspection